One-stop data solutions for

supply chain due diligence.

G360 provides a cloud-based data platform and a suite of tools to help your business monitor and manage your supply chain’s environmental, social, and governance (ESG) risks.

The Due Dilegence Challenge

Supply chain due diligence is not a one-time activity but an ongoing process. It should be based on a systematic process to identify and manage ESG risks and remediate negative impacts. It involves suppliers, third party service providers, and internal stakeholders. A strong data supported program can bring real benefits to the company if it is done correctly.

It's All About Data

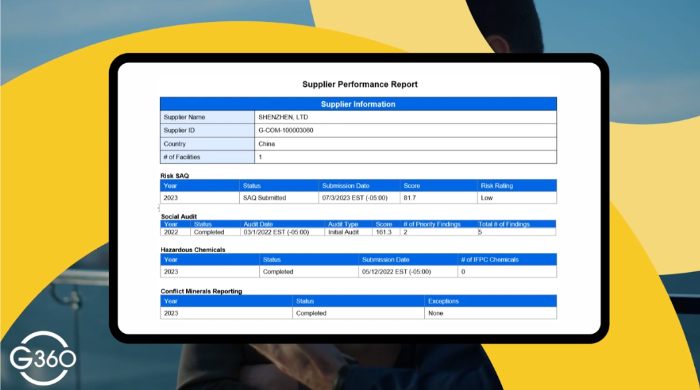

From centralized supply lists and supplier profiles, mappings based on your products or services, program activities such as audits, surveys, or self-assessments, to corrective actions and risk assessments, you need the relevant data to manage your activities and make sense of your program impact.

What makes it more challenging is that most data requires collaboration from service providers such as an audit firm or from the suppliers directly. After you get the data, in most cases, you need to cleanse and normalize the data in PDF or Excel formats to truly fit your tracking requirements.

Why G360?

G360 Insights® is expertly designed for companies looking for a holistic and risk-based data platform to manage their supply chain due diligence.

Core Capabilities

Data Collection

Collect data from third-parties vis surveys, self-assessments, audit reports, and corrective action updates.

Workflow

Automate your policies and requirements to configurable workflows with tasks, alerts, and notifications to both internal and external stakeholders.

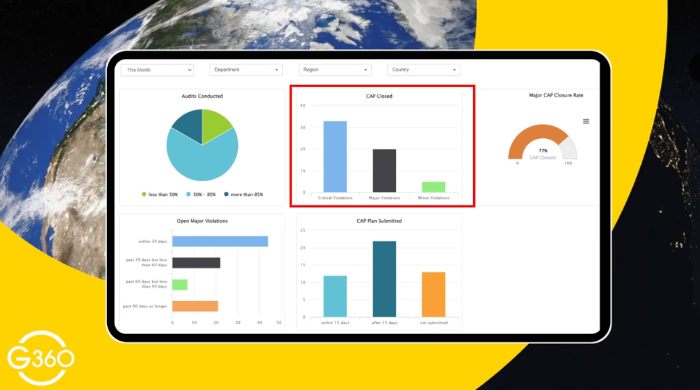

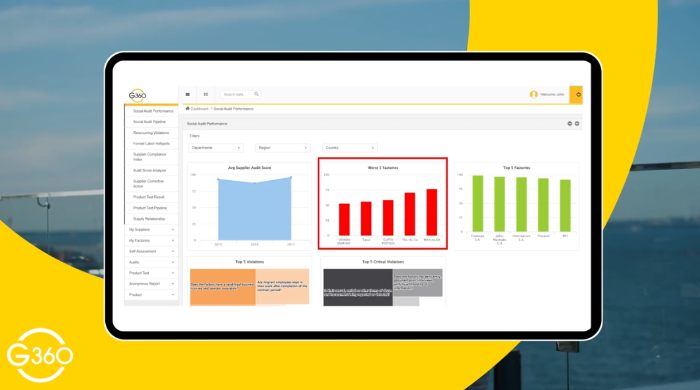

Reports & Dashboards

AI-Powered Data Processing

Leverage AI to make your ESG due diligence data searchable and intelligent.

Proven Success

G360’s one-stop data solutions are battle-tested. We have helped companies in their supply chain due diligence journey.